The Race to Replace Fossil Fuels

Synthetic fuels could hold the key to decarbonizing transport and fighting climate change.

Researchers hope to power planes with fuel synthesized from air, water, and sunlight. Will they succeed quickly enough for our changing climate?

When Lauren Rowello bought a car in 2019, she wanted it to be as sustainable as possible. Considering a range of factors, the Philadelphia resident settled on a used electric vehicle, a Tesla Model 3: “I didn’t want to support problematic work conditions that I’ve read about at Tesla plants, and I didn’t want to use new materials that a brand new car would require.”

Unfortunately, Rowello found that making her commute carbon-neutral wasn’t as simple as hopping into a second-hand electric car. “We… were disappointed to learn that some of the charging stations were run off coal in other parts of the US,” she says. “In our own area, they’re still mostly using natural gas. So…the fuel I’m using is not carbon-neutral.”

Rowello is far from alone in wanting to reduce her transport-related contributions to climate change. The United Nations calls climate change “the defining crisis of our time,” and has set a goal of reducing emissions to net zero by 2050 (meaning emissions from human activities will be less than or equal to the carbon removed from the atmosphere through processes like photosynthesis and carbon capture). To meet that goal, we must reduce emissions by 45% in the next decade, and much of that reduction will have to come from transport.

Almost 95% of the world’s transportation energy still comes from petroleum-based fuels.

Prior to the Covid-19 pandemic, fuel combustion for transport of cargo and passengers accounted for 24% of carbon dioxide (CO₂) emissions worldwide. Despite significant growth in alternative energy sources, almost 95% of the world’s transportation energy still comes from petroleum-based fuels like gasoline and diesel, according to the US Environmental Protection Agency.

The pandemic may have put a temporary damper on our fuel needs, but forecasts from the International Energy Agency indicate that demand for transport fuel is expected to continue to rise through 2040, and maybe even beyond. Even though the share of renewables is likely to increase, the consumption of fossil fuels is predicted to rise as well.

Reducing transport emissions isn’t just an environmental issue, it’s also about social justice. Kelly Fleming, an analyst at UC Davis’ Policy Institute for Energy, Environment, and the Economy, wrote about social equity and transportation in a 2018 article for the Journal of Science Policy & Governance: “Low-income populations, which also are disproportionately people of color and people with disabilities… tend to live in areas that disproportionately suffer from health consequences and other negative externalities… associated with transportation congestion and emissions.” All the more reason to decarbonize transportation.

To meet the UN’s net-zero target by 2050, replacing fossil fuels with carbon-neutral alternatives is a matter of priority. A 2019 policy briefing from the Royal Society (the UK’s national science institution) touched on proposals from electrification to hydrogen power, but spotlighted synthetic fuels as a promising long-term solution. There are some critical roadblocks to their adoption, though, including lowering costs and scaling up production to meet demand.

Electrifying possibilities

Thanks to the worldwide increase in renewable electricity, the Royal Society briefing states that “Considerable progress towards the decarbonisation of transport is promised through the electrification of passenger vehicles.” Unfortunately, the advances made in developing cars like Rowello’s Tesla aren’t applicable to heavier forms of transport, which require different technologies.

“Aviation and maritime [are] both difficult areas to decarbonize,” says Graham Hutchings, a chemistry professor at Cardiff University who was part of the team behind the Royal Society briefing. A key consideration when adopting batteries as a fuel source is the ratio between how much energy a unit carries, and the space it takes up. Existing battery technology, Hutchings says, doesn’t yet offer an energy-to-volume ratio efficient enough for trucks, planes, and maritime freighters. They will have to depend on combustion fuels until better battery technology is developed.

People of color and people with disabilities tend to live in areas that disproportionately suffer from health consequences associated with transportation.

With oil prices at a historic low — this year, crude has averaged around US$40/barrel, or $0.25/litre — the shipping industry has no financial incentive to develop that technology. “There’s plenty of oil sloshing around in the world right now,” says an American industry expert from a non-profit energy and environmental research organization. He asked for his comments to remain anonymous as staff are discouraged from speaking publicly about their work. “It’s a lot easier to justify [clean energy] when fossil fuel prices are high, because you’re offsetting a more expensive commodity.”

Until that changes, researchers are working on strategies for partial electrification, like a NASA-supported study on using batteries to supplement aircraft fuel. The researchers studied the trade-off between fuel savings and battery costs (including the carbon impact of the electricity for recharging), and developed modelling tools engineers could use to create better batteries for aircraft.

Alternatives to the alternative

Another promising development for decarbonizing transport is “green ammonia,” created by splitting water molecules with sustainable electricity to extract hydrogen, which is then combined with nitrogen captured from air. The resulting ammonia can be burnt as a non-emitting fuel or used to store energy.

The Royal Society identifies maritime shipping as a potential early adopter because the widespread use of ammonia as an agricultural fertilizer means a global network of ports where it’s traded and infrastructure for storing ammonia on ships already exist. Down the line, green ammonia could also potentially be used to decarbonize rail, heavy road transport, and aviation. While the manufacture and distribution of ammonia are well established, transitioning to using it as an energy carrier and fuel needs careful risk assessment, given that it is a highly corrosive chemical, with associated health and environmental hazards.

“Green ammonia” has been proposed as a potential low-carbon fuel source for maritime shipping.

Other researchers suggest transitioning to a hydrogen economy. Hydrogen can be produced from water using clean electricity, and emits no greenhouse gases when used as fuel. A team at Austria’s International Institute for Applied Systems Analysis (IIASA) has made a case for bringing airships back to the skies, using the pressurization and depressurization of hydrogen for lifting and landing. Propelled by the jet stream, airships could be a faster, green alternative to highly polluting maritime shipping.

“Airships and balloons have the advantage of reaching locations with difficult access in the middle of the continent,” says the IIASA study. “This could reduce the cost of transportation of goods produced by or delivered to cities far from the coast. Countries that do not have access to the ocean would also benefit…” It is still early days for the technology, though. Regulatory frameworks and long-term strategies are needed to attract investments, scale up to reduce costs, shift to low-carbon hydrogen, and extend the use of hydrogen to more applications.

Fuel from air and sunlight (or manure!)

According to the Royal Society briefing, the best bets for a faster transition to clean transport are carbon-based synthetic fuels that can replace existing fossil fuels. Two broad categories of synthetic fuel are currently in development: electrofuels and synthetic biofuels.

Electrofuels (or efuels for short) are synthetic fuels whose production is powered using electricity. For efuels to be carbon-neutral, that electricity needs to come from carbon-free sources. Efuels can be produced more or less out of thin air, as a research team from Swiss science university ETH Zurich demonstrated in 2019. In a process similar to green ammonia manufacture, they captured CO₂ and water vapour from the air, and used solar electricity to generate aviation fuel.

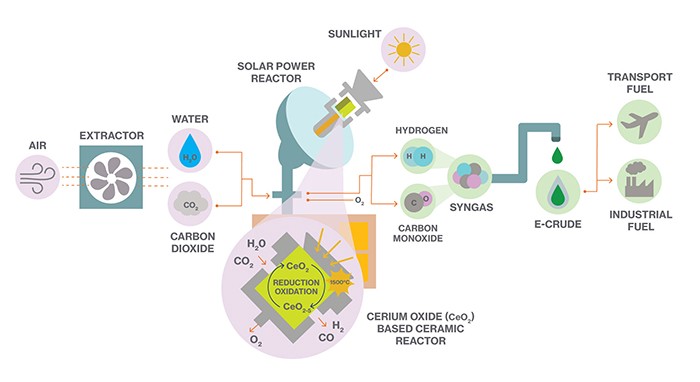

In the ETH method, CO₂ and water extracted from the atmosphere were fed to a solar-powered reactor installed on the lab’s roof. Inside the reactor, concentrated sunlight creates high temperatures (up to 1,500ºC). The interior of the reactor is a ceramic made of cerium oxide (CeO₂), in which an oxidation-reduction reaction takes place. In the reduction step, heat removes oxygen from CeO₂. Next, CO₂ and water are added, which produces “syngas,” a mixture of hydrogen and carbon monoxide. The remaining oxygen is taken up by the reactor’s ceramic interior to form CeO₂ again (oxidation), making it ready to start the process all over again.

The ETH Zurich method of efuel generation

Syngas can be converted into a crude oil substitute, which can then be refined into fuels including jet kerosene and gasoline. “CO₂ captured directly from the air is able to close the carbon cycle,” says Aldo Steinfeld, the lead scientist on the project. “The synthetic fuels derived this way are truly carbon neutral because their combustion emits as much CO₂ as [is] extracted for their production.”

And then there are biofuels — like biodiesel and bioethanol — which are made using various chemical, thermal, and biological processes. For instance, “gasification” involves treating biomass with oxygen at high temperatures without combustion to produce a mixture of hydrogen and carbon monoxide similar to syngas, plus a small amount of CO₂.

Source materials for biofuels abound: plant, agricultural, and animal waste, algae, cooking oil and food scraps, sewage sludge, industrial effluents, fishery and forestry products, and other organic materials. For example, in California’s Central Valley, a “dairy digester pipeline” produces natural gas from cow dung that fuels about 400 waste-hauling trucks. Calgren Renewable Fuels captures methane from the decomposing cow manure and injects it into the pipeline network owned by Southern California Gas Company.

The big advantage of synthetic biofuels and efuels is they can be manufactured as “drop-in” replacements for fossil fuels.

One promising biofuel project out of the EU is TO-SYN-FUEL, which aims to produce synthetic fuels from organic waste biomass, mainly sewage sludge. The technology, which has already been demonstrated on a pilot scale, can produce renewable liquid fuels like gasoline and diesel.

But not all biofuels are created equal. “People often overlook the…life cycle impact,” says the anonymous energy researcher quoted above. “If you…harvest trees to make them into wood chips to turn into a biofuel…[then you] deal with the impact of that rainforest going away.” Energy crops occupying land needed for food crops are equally problematic.

Biofuels made from waste materials, however, do create carbon cycles that are as sustainable as efuels’. In that scenario, atmospheric carbon is cycled through the growth of plants or animals and whatever process creates the waste material, which is then converted into fuel whose combustion releases the carbon back into the atmosphere.

The UK’s Royal Society estimates that synthetic diesel is likely to cost more than five times the current price of diesel made from fossil fuels.

The big advantage of synthetic biofuels and efuels over other low-carbon alternatives is they can be manufactured as “drop-in” replacements for jet fuel, gasoline, diesel, and marine fuel. A drop-in fuel is a synthetic, renewable substitute for conventional petroleum-derived fuels that can work within current petroleum infrastructure — like pipelines and existing vehicle engines — or be blended with petroleum products. But we’re not quite there yet.

“With appropriate design, eventually one will be able to get close” to a fully carbon-neutral synthetic fuel, says Cardiff’s Hutchings. “But improvements are needed in all of these steps, so research and development is required.”

Roadblocks to decarbonized transport

As yet, there are many challenges to scaling up the production and use of synthetic fuels. These include: the need for better ways to convert water to hydrogen, and financial challenges like producing green hydrogen at scale affordably and developing sources of competitively priced low-carbon energy.

The single biggest roadblock is cost. As with Rowello’s Tesla, it’s critical that the production of synthetic fuels relies on renewable electricity if it’s going to reduce carbon emissions. And renewable energy doesn’t come free. ETH’s Steinfeld estimates the current cost of solar jet fuel produced by the method he works on is about US$2/L, which is seven times the cost of jet fuel produced from petroleum.

While no industrial-scale plants for synthetic fuels have been built yet, the Royal Society calculates synthetic diesel will cost around US$5/L, varying based on the cost of green electricity. Diesel made from fossil fuels currently averages US$0.86/L globally. “Without further development and scale up,” says the Royal Society, “efuels are unlikely to be economically competitive in the 2030 period without government support.”

Promising research released earlier this year suggests affordable biodiesel made from sewage may soon be a reality.

Despite these challenges, a number of companies are looking to bring synthetic fuels mainstream. Synhelion is a commercial spin-off of the ETH project that aims to replace all fossil fuels with economically viable carbon-neutral drop-in fuels that are fully compatible with current fuel infrastructure. In the short term, they’re trying to bring a solar jet fuel to market by 2022. German renewable energy company Sunfire plans to build a production facility in Norway by 2022 to produce a crude-oil substitute with a target price of below US$2/L.

Canadian company Carbon Engineering plans to build what they claim will be the world’s largest direct air-capture facility in Squamish, BC. It’s expected to remove up to 1 million metric tonnes of CO₂ from the atmosphere every year. The captured CO₂ could be permanently stored underground (to reduce atmospheric carbon) or synthesized into clean fuels. At present, the fuel they make is consumed in their own research, but they have plans to start building commercial plants for carbon capture and fuel manufacture by 2021.

There is also still a need for more research into synthetic-biofuel production at scale using non-fossil-fuel energy. This February, scientists from the Québec-based Institut National de la Recherche Scientifique (INRS) published their findings on a method of fermenting sewage sludge and glycerol with microorganisms to produce biodiesel under US$0.72/L if manufactured in a 20 million L facility. With the pandemic bringing everything to a standstill, it’s no surprise that commercialization plans haven’t yet been announced. Hopefully as the dust settles, this method for making biodiesel more cheaply than conventional diesel will find its way to market. Especially since the researchers behind it are exploring ways to make it even more cost-effective.

Cleaning up our act

“As the costs of batteries and other technologies continue to drop, and the electrical grid continues to clean up, electric vehicles are likely to dramatically improve the way we travel and the air we breathe,” says Kelly Fleming, the UC Davis policy analyst. However, she believes the combination of Covid-19’s economic impact and historically low oil prices will likely hinder a larger transition to clean fuels.

ETH researcher Aldo Steinfeld, on the other hand, believes the impacts of Covid-19 on synthetic-fuel development will be short-lived. “Oil prices will eventually increase and even exceed the levels before the corona crisis as external costs caused by greenhouse gases and other pollutants are internalized,” he says. “Thus, [research] on solar fuels should continue.”

Nico Ulbicht, Sunfire’s PR person, believes low oil prices should not hamper the adoption of clean energy to the transport sector. “Regulations such as CO₂ prices and regulatory frameworks with quotas should help [make] transportation sustainable,” he says.

Oil prices will eventually exceed previous levels as external costs caused by greenhouse gases are internalized.

Despite the uncertainties caused by the global pandemic, companies are moving forward on synthetic fuel projects. Norsk e-Fuel — a collaboration between Sunfire, Climeworks (another ETH spin-off that does carbon capture), and others — is building Europe’s first commercial plant for renewable jet fuel. In June, Ulbicht said the pandemic had not affected their plans: “The project officially started this month.” It’s on track to start industrial-scale production by 2022.

Whether the post-pandemic environment is favourable for synthetic fuels “will depend on the way governments react,” Fleming says. “There is an opportunity to use this as an economic stimulus… creating new innovative jobs that will help us reduce our emissions.”

From the driver’s seat of her Tesla, Lauren Rowello hopes those in power take that opportunity: “There’s never going to be the right answer for everyone working within an industry. We need to train people…and get them excited about the possibility to do that work.”

Print Issue: Summer/Fall 2020

Print Title: Are we there yet?